Crux Agribotics launches SortiPack system for automated Grading, Sorting and packing at Greentech 2019. SortiPack is a fully automated system that enables the agriculture industry to anticipate upon market-growth and shortage of labour. Worldwide we see scarcity of human labour as an increasing factor of uncertainty in food-processing companies.

What does Sortipack offer me?

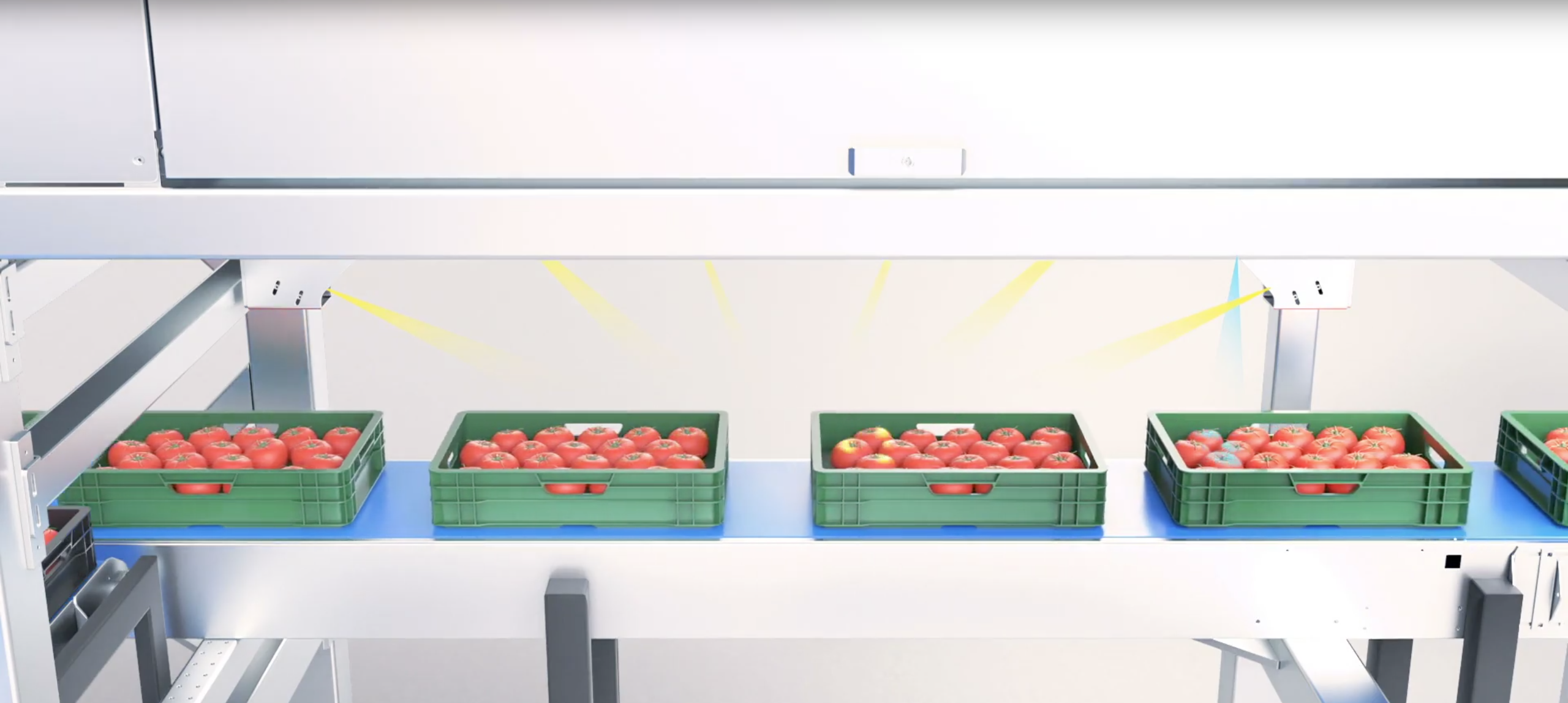

With SortiPack we offer one footprint in which bulk harvested fruit or vegetables are individually packed in a controlled way. Our vision-system combines 2D and 3D imaging and smart classification algorithms to determine the optimal destination of each individual product, grading in optimal uniformity and minimizing the give-away weight.

Grading and sorting is performed real-time up to 20.000 pieces per hour, depending number of classes, weight and size of the actual product. This enables growers to scale up, ultimately to 24/7 operations, whilst automation decisions are objective, constant and consistent instead of human subjectivity.

In the fast-changing world we live in, there are new value-streams coming up in the form of data.

Data about your harvest, product-quality and packing is digitally available. This enables growers to assess quality real-time and also take predictive measures such as selling its yield in advance at the best price. Based on the actual yields, the SortiPack system will also make automatic suggestions to optimize the sorting classification based on set parameters such as dimensions, weight and product quality. Imagine what these insights can mean for your continuous improvement process and yield optimization.

Why is 2019 is the time to start investing in innovation?

We believe there are many reasons to invest in innovation. SortiPack combines the following four reasons:

- Our technology on vision and robotics has been proven in industrial environments

- Automated routines are faster and more consistent than humans

- Reliable data enables better trading and offers additional insights

- The system is also available in an OPEX business model, SPaaS (Sort and Pack as a Service) where the majority of the investment is paid in a ‘pay-as-you-use’ model. (link naar ander nieuwsbericht)

Quality First

Physically we can rely on world-class components and a robust design. Whether this may be the ABB delta-picking robots, or the super-sensitive grippers, machine and product-quality always come first.

Less tangible is the system’s intelligent software which offers you quality as well. Depending on your requirements and chosen options and configuration, the software will prevent any low-grade product from being placed between -and possibly infect- the good output. This quality inspection can apply to visual and non-visual criteria. Learn more about the Quality Assurance features which Sortipack has to offer!

Live demo SortiPack

Let SortiPack prove itself by handling your products. Crux Agribotics has invested in a SortiPack (Triple Robot Edition) on which we handle a variety of products already.

Challenge us if you have another product than cucumber, tomatoes and peppers which we are already handling. Depending your interest and desire we will invest in building a proof of concept and demonstration with your product. We hope to welcome you at our demonstration during #Greentech 2019, hall 11, booth 11.304